When you hold a one rupee coin in your hand, you may think its value is equal to its face value. But the reality is different. According to a disclosure made by the Reserve Bank of India (RBI) in response to an RTI in 2018, it actually costs more to produce a one rupee coin than the coin itself is worth. The manufacturing cost of one rupee is around Rs 1.11.

This fact surprises many people because it raises questions about why the government continues to mint coins that cost more than their value. To understand this better, let us explore the process of coin manufacturing in India, the costs involved, and why coins remain in circulation despite these higher costs.

The Real Cost of Coins in India

The manufacturing cost of one rupee is not the only surprising figure. Costs for other coins have also been revealed:

- Rs 1 coin: Rs 1.11

- Rs 2 coin: Rs 1.28

- Rs 5 coin: Rs 3.69

- Rs 10 coin: Rs 5.54

This means that for every Rs 1 coin produced, the government spends 11 paise more than its actual value. However, when we look at higher denomination coins like Rs 5 and Rs 10, they are still produced at less than their face value. That makes them more cost-effective in terms of manufacturing.

Why Does It Cost More to Make a Coin?

The cost of minting coins depends on several factors:

- Raw materials – Metals like stainless steel, nickel, and copper are used to make coins. Their prices in the global market directly affect the production cost.

- Manufacturing process – Coins require specialized machinery, labor, and technology.

- Security features – Each coin has specific designs and embossing to prevent counterfeiting.

- Logistics – Transporting coins from mints to banks across India also adds to expenses.

When all these factors are added, the manufacturing cost of one rupee becomes higher than its value.

What About Rs 2, Rs 5 and Rs 10 Coins?

While the one rupee coin costs more than its value, the case is different for higher denominations.

- Rs 2 coin costs Rs 1.28. Here, the government spends less than the coin’s value.

- Rs 5 coin costs Rs 3.69, which is cheaper than Rs 5.

- Rs 10 coin costs Rs 5.54, making it very cost-effective compared to its value.

This is why minting larger denomination coins is more economical for the government. They give higher value in exchange for lower production cost.

Who Prints Indian Currency?

The printing and minting of Indian currency is a shared responsibility between the Government of India and the Reserve Bank of India.

- The Government of India prints Rs 1 notes and all coins.

- The Reserve Bank of India (RBI) prints notes from Rs 2 to Rs 500.

- Earlier, RBI also printed Rs 2000 notes, but they have now been withdrawn from circulation.

Coins are minted in Indian Government Mints (IGM) located in Mumbai and Hyderabad. While Hyderabad Mint disclosed the cost of production through RTI, Mumbai Mint declined citing confidentiality under Section 8(1)(d) of the RTI Act, 2005.

Features of the One Rupee Coin

The Rs 1 coin is made of stainless steel and has the following features:

- Diameter: 21.93 mm

- Thickness: 1.45 mm

- Weight: 3.76 grams

These specifications make the coin durable and easy to use in daily transactions.

Why Keep Making One Rupee Coins Despite High Costs?

This is a question many people ask after learning about the manufacturing cost of one rupee. If it costs more than its value, why is the government still producing it?

Here are the reasons:

- Public Usage – One rupee coins are widely used in daily life, especially for small transactions.

- Cultural Value – Rs 1 holds a special place in Indian traditions, often used in ceremonies, charity, and as a token of good luck.

- Financial Inclusion – Coins ensure accessibility for everyone, especially in rural areas where digital payments are not common.

- Durability – Unlike notes, coins last much longer and can be used for years.

Thus, even though the manufacturing cost of one rupee is higher, the social and economic reasons justify its production.

Impact of High Manufacturing Costs

The rising costs of raw materials and minting create financial pressure on the government. Some impacts include:

- Losses on small denomination coins like Rs 1.

- Focus on higher denomination coins to balance costs.

- Encouragement of digital payments to reduce dependency on physical currency.

Still, coins remain important for millions of people in India who rely on cash for their everyday needs.

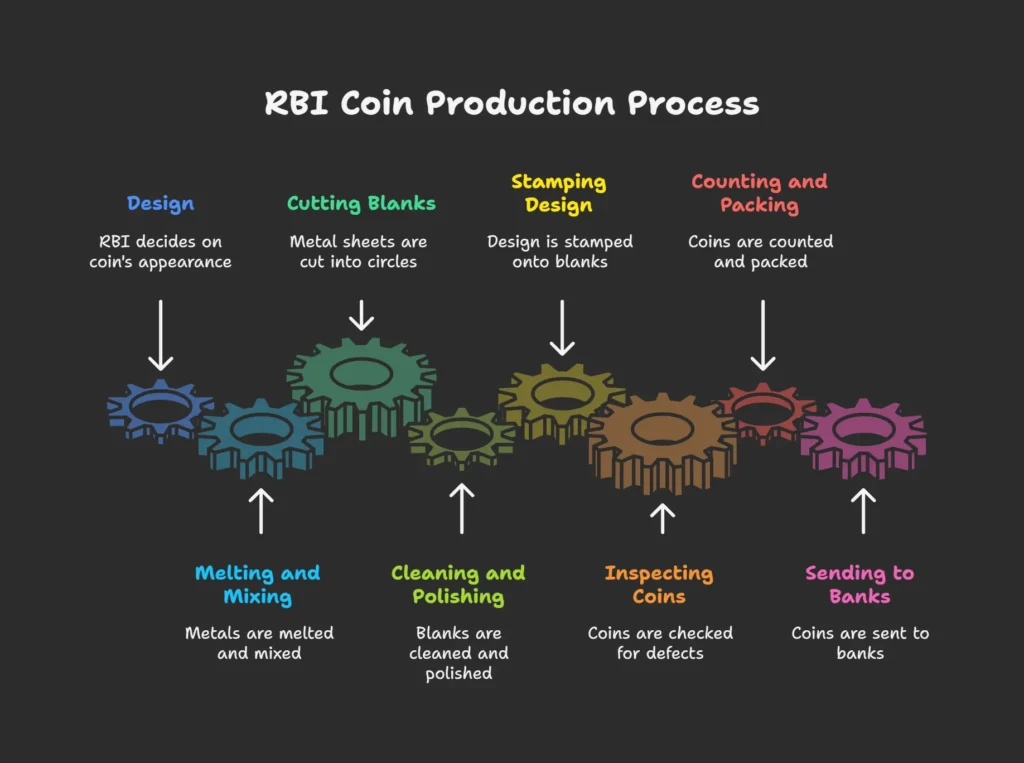

Manufacturing Process Of Coin RBI

This document explains how the Reserve Bank of India (RBI) produces coins in a way that even a child can understand. We’ll use simple analogies and examples to break down the process, from designing the coin to finally putting it into your piggy bank!

Imagine you’re making cookies! Making coins is a bit like that, but instead of dough, we use metal, and instead of an oven, we use giant machines!

1. The Idea (Design):

- What it is: Before we even start making coins, someone has to decide what the coin will look like. This is like deciding what shape your cookie will be – a star, a circle, or maybe even a dinosaur!

- How it works: The RBI decides what pictures and numbers will be on the coin. They think about important things in India, like animals, famous people, or important buildings. They also decide how much the coin will be worth – like 1 rupee, 2 rupees, 5 rupees, or 10 rupees.

- Kid analogy: It’s like drawing a picture of your favorite toy and deciding how much it “costs” in your pretend shop.

2. Making the Metal (Melting and Mixing):

- What it is: Coins aren’t made of just one metal. They’re made of a mix of different metals, like copper, nickel, and steel. This makes them strong and shiny.

- How it works: Big factories melt these metals in huge pots, like melting chocolate to make a chocolate bar. Then, they mix them together in the right amounts to make a special “coin metal.”

- Kid analogy: It’s like mixing different colors of playdough to make a new color. You need the right amount of each color to get the color you want.

3. Cutting the Blanks (Punching Out Circles):

- What it is: Now that we have the “coin metal,” we need to cut it into the right shape – a circle! These circles are called “blanks.”

- How it works: Big machines use a special punch to cut out lots and lots of these blanks from the metal sheets, like using a cookie cutter to cut out cookies from dough.

- Kid analogy: It’s like using a cookie cutter to make lots of cookies from a big sheet of dough.

4. Cleaning and Polishing (Making Them Shiny):

- What it is: The blanks are a little rough around the edges, so we need to clean them and make them shiny.

- How it works: The blanks are put into big tumblers, like giant washing machines, with special cleaning materials. This makes them smooth and shiny.

- Kid analogy: It’s like polishing your shoes to make them look nice and clean.

5. Stamping the Design (Adding the Pictures and Numbers):

- What it is: This is where the coin gets its special design – the pictures, numbers, and words that tell us what it is.

- How it works: The blanks are put into a big machine called a “coin press.” This machine has two “dies,” which are like stamps with the coin’s design on them. The machine presses the dies onto the blank with a lot of force, leaving the design on the coin.

- Kid analogy: It’s like using a stamp to put a picture on a piece of paper.

6. Inspecting the Coins (Checking for Mistakes):

- What it is: After the coins are stamped, we need to make sure they’re all perfect.

- How it works: People and machines check the coins for any mistakes, like scratches or blurry designs. Any coins that aren’t perfect are taken out.

- Kid analogy: It’s like checking your homework to make sure you didn’t make any mistakes.

7. Counting and Packing (Getting Ready to Spend):

- What it is: The good coins are counted and packed into bags and boxes.

- How it works: Machines count the coins very quickly and put them into bags. These bags are then packed into boxes and sent to banks all over India.

- Kid analogy: It’s like counting your toys and putting them in a box to take to a friend’s house.

8. Sending to Banks (Ready for Your Piggy Bank!):

- What it is: The banks give the coins to people when they need them.

- How it works: When you go to the bank and ask for money, the bank might give you some coins. These coins were made in the factory using all the steps we talked about!

- Kid analogy: It’s like going to the store and buying something with your allowance. The store gets the money from the bank, and the bank got the money from the RBI!

So, the next time you see a coin, remember all the steps it took to make it! From the idea to the metal to the stamping, it’s a long and interesting process. And just like making cookies, it takes a lot of work and special machines to make something so small and useful!

Final Thoughts

The manufacturing cost of one rupee is higher than its value, but coins continue to play an important role in India’s economy and culture. While it may not make financial sense at first glance, coins are essential for smooth cash transactions, traditional uses, and inclusion of all sections of society.

As India moves toward digital payments, the role of coins may reduce in the future. However, for now, one rupee coins remain a necessary part of our daily lives despite their high production cost.

Disclaimer

The information provided in this article is based on publicly available data, including disclosures by the Reserve Bank of India (RBI) through RTI in 2018. Costs may vary with changes in raw material prices and government policies. This article is for educational purposes only and should not be considered financial or legal advice.